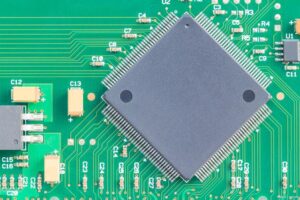

SMT: Abbreviation of Surface Mount Technology in English, which in Chinese means surface mount technology, the technology of welding electronic parts to the surface of a circuit board. SMD: Abbreviation of Surface Mount Device in English. In Chinese, SMD refers to surface mount welding parts, and generally refers to electronic parts that can use SMT technology. Generally, SMT and SMD can be mixed, but there are still some differences (I won’t elaborate here).

General normal solar panel process: sorting – slicing – breaking – Serial welding – Welding – lamination – lamination – Cleaning – packaging. The SMT chip solar panel process: sorting – slicing – breaking – SMT chip – laminating – cleaning – packaging. At the beginning, SMT technology was not used on solar panels, but was first used for welding electronic parts to circuit boards. SMT chip solar panel also uses solder paste to print on the bonding pad of the solar cell chip to be welded, and then put the battery chip on it. The solder leg should be just on the solder paste position, so that the solder paste can pass through reflow soldering. The high temperature in the furnace should be higher than the solder paste melting point (remember not to be too high to avoid burning the circuit of the circuit board). The high temperature of the furnace melts the solder paste, and after it is cooled out, the solder paste becomes solid (this principle is a bit like that EVA is solid before entering the laminator, becomes liquid after high temperature during lamination, and finally becomes solid after lamination). Then the solar cell chip can be directly welded to the PCB board.

Generally, the solar cells used for SMT are Sunpower solar cells, because the positive and negative poles of Sunpower solar cells are on the back, and the space between the positive and negative poles of each group is small, which can be cut into smaller solar cells. The finished product size of the smaller solar panel made by Sunpower is 27 * 11mm. This also highlights the advantages of using SMT patches:

It can meet the requirements of making smaller electronic products, making the products lighter and smaller.

It is suitable for mass production and batch operation, making the quality more stable.

The production cost is reduced, the working procedure is reduced, and serial welding and welding are not required.

More widely used, it can be used in military (sight), forest camera and GPS locator.

But there are also some drawbacks: the power produced by it is limited, which is mainly affected by the machine more, mainly for small power solar panels.

27 * 11mm solar panel

If you want to know more about solar panels, please pay attention to Huanqi Technology (Shenzhen) Co., Ltd.